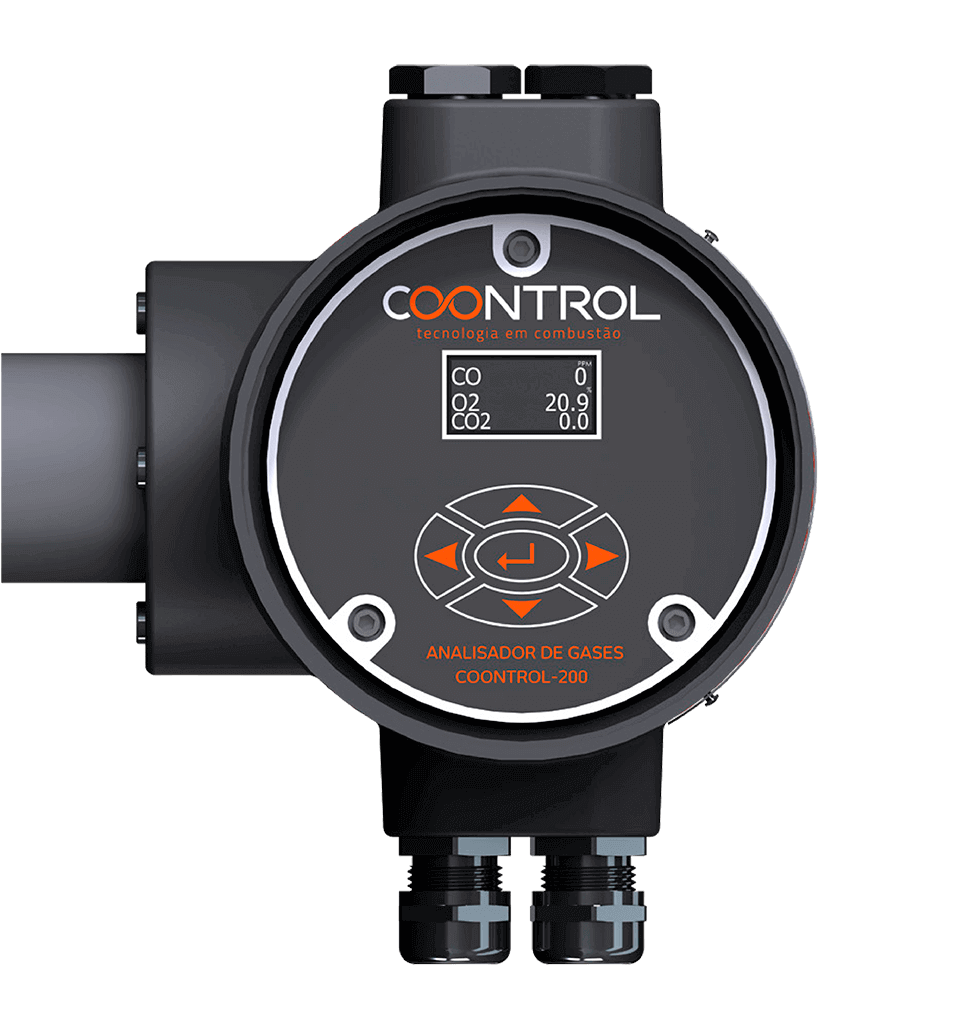

CO2, O2, and CO Gas Analyzer - COONTROL 200

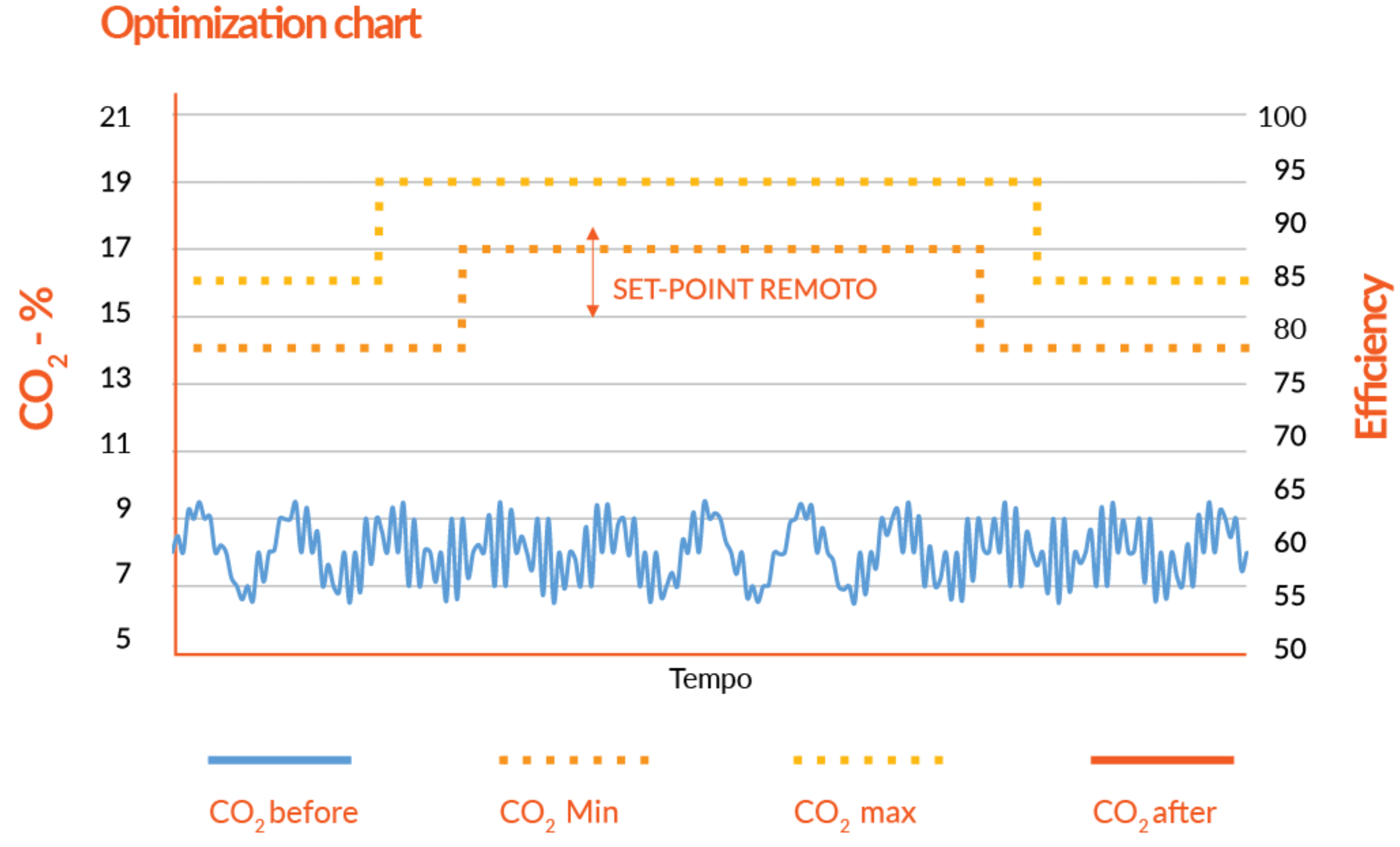

Reduce costs and increase boiler efficiency with COONTROL 200! The gas analyzer reduces fuel consumption by controlling boilers’ CO, CO₂, and O₂.

The solution is recommended for a wide variety of fuels, such as biomass, natural gas, GMP oils, and more!

COONTROL 200 is recommended for a wide variety of biomass, natural gas, GMP oils, and more!

Fuel reduction: gas control optimizes boiler combustion by feeding biomass and reducing excess air;

Reduction of polluting gases: efficient combustion reduces the emission of polluting gases that cause the greenhouse effect.

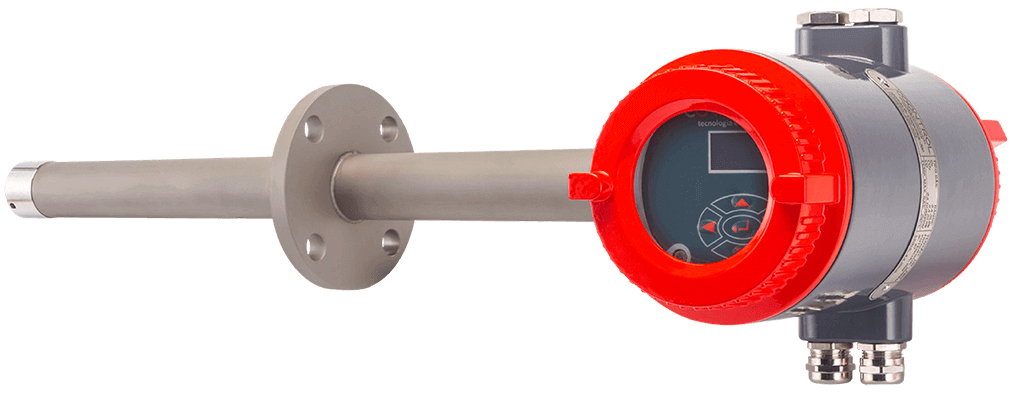

Robustness: made of a thick injected aluminum capsule, finished with electrostatic paint and electronics resistant to high temperatures;

Measurement method: In Situ, guaranteeing reliable real-time measurements.

The analyzer can be used in several industries: sugar and alcohol, paper, agro-industrial, textile, food, refrigerators, beverages, biodiesel, furniture, and wood, among others.

In addition, COONTROL 200 has European conformity certification (CE marking) and a patent recognized by the National Institute of Industrial Property (INPI). As a result, it guarantees a rating of excellence, safety, originality, and on-board technology! COONTROL is also associated with technology centers. This ensures continuous participation in the development of new ideas and product evolution.

Thus, it is the company's concern:

Ensure the development of products with cutting-edge technology;

Safety and operability of the equipment;

Maintaining the knowledge of the development and services team;

Certifying the qualification of products;

Proof of results.

Controlling these gases makes it possible to optimize boiler combustion, reducing fuel consumption and greenhouse gas emissions.

All the improvements provided by the COONTROL 200 equipment are reflected in significant savings of up to 20% in fuel consumption.