Como uma fábrica no RS economizou quase R$ 4 milhões no ano com COONTROL: automação no recebimento de biomassa e monitoramento com o SMB300.

O desafio da indústria petroquímica: vapor caro e biomassa imprevisível

Sua indústria compra vapor de terceiros e sente o impacto no seu lucro? Esta petroquímica do RS enfrentava esse mesmo desafio.

Mesmo tentando gerar vapor internamente com biomassa, esbarraram em combustível imprevisível e falhas de qualidade… E o custo continuava alto.

A automação COONTROL como resposta: CRE-Bio + SMB300

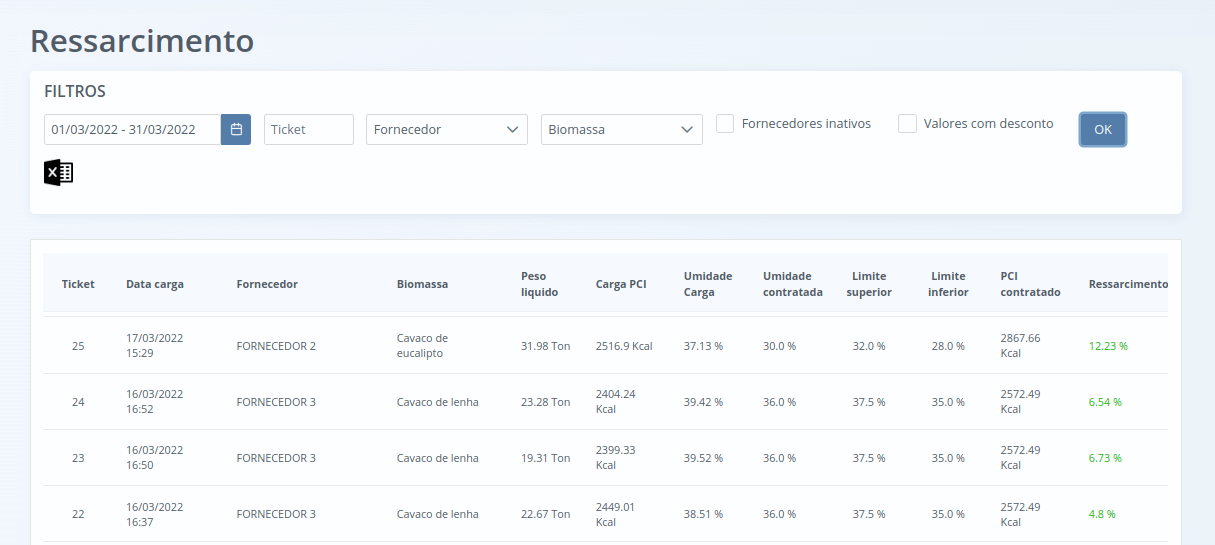

Foi quando a COONTROL entrou com o SMB300, garantindo medição de peso, umidade e volume da biomassa em tempo real…

E gerando bilhetes com QR Code para cada carga por meio do CRE-Bio (plataforma de logística e gestão que compensa via bilhetes QR Code).